VIBHUTI

BHATT

YouSolar Inventory System

Design a system that automates the inventory management

Project Overview

YouSolar is a startup and catching up with the production of PowerBlock. Initially, the project was to create a shelving system and keep the system lean. I was assigned to design labels to optimize time and accuracy. In my research, I found that Our team was short-staffed and struggling to update inventory status manually. Hence, I strategized, designed, and built a process to streamline our inventory access and report creation.

Role

Product Designer

Content Strategy

Methods

Interview

Coding

Critical Thinking

Tools

Adobe XD

Google Scripts

QR code

Duration

2 months

Team

Vibhuti (Designer)

Baxter (Operation Support)

Lisa (Supply chain manager)

Problem

● Unsupervised

Everyone in the company has access to inventory, and it often happens that someone forgot to update the inventory sheet. It was affecting the inventory cost report too.

● Running behind product delivery schedule

The lack of accurate numbers in inventory led our supply chain manager to plan for reordering later than expected. It causes a delay in the final delivery of the manufactured product.

How might I streamline the process for the Inventory head and supply chain manager to increase accuracy?

Solution

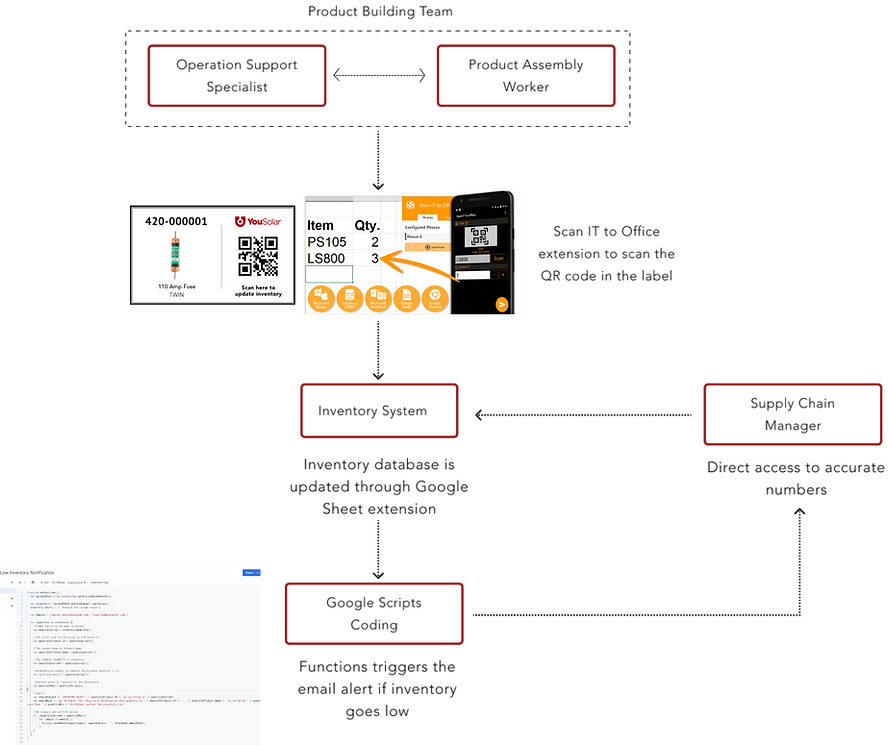

● Automation of inventory change

Newly designed Inventory part label consisting of QR codes and synced with Google sheets. An automated process to update inventory status by scanning code.

● Low inventory alerts

The supply chain manager will receive alerts through Google scripts whenever there is low running inventory. Google sheet functions are used to customize individual parts' minimum required quantity based on the time it takes to order and receive from the distributor.

01

Curiousity

My curiosity led me to...

I interviewed users, the product installer, operation Support specialist, and supply chain manager, who has access to inventory. I was curious to know their roles, goals, and frustrations with using the manual inventory system to communicate. I created user flows and charts to map how information flowed between these individuals in a typical product assembly cycle.

Where was the information gap?

-

Everyone is accessing inventory, and there is a higher probability that someone may forget to update it.

-

The Supply chain manager is not receiving accurate numbers and time to order.

-

Inaccurate supply chain planning and delivery caused irregular delivery of the final product.

-

The finance team had difficulty figuring out the total inventory cost for financial audits.

02

Define

❓Current Information Architecture with reverse information flow

A. Inaccurate number

During product assembly, there may be defective parts are being discarded. The inventory update system flows in the reverse direction, and these parts are not in the calculation. Because of these uncalculated parts, the overall inventory number is high when in reality, it is low.

B. Wrong timeline

Because of inaccurate inventory numbers and the supply chain manager does not receive requirements from the product building team, there was a delayed reordering. This delay was causing irregular final product delivery and customer complaints.

03

Design

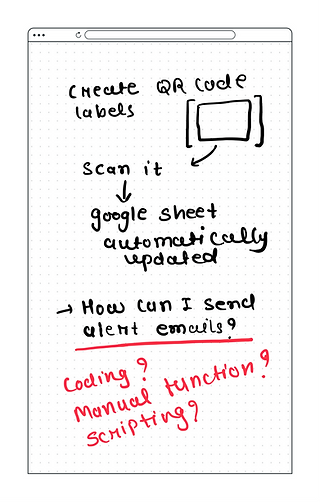

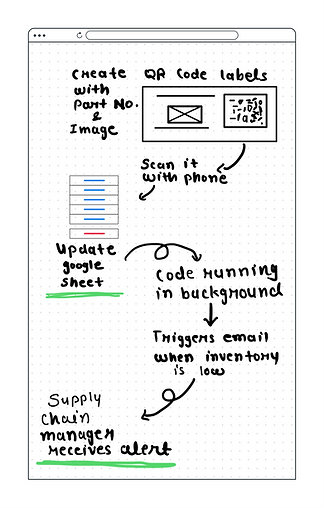

Supply chain manager was out of loop and reordering will not happen on time.

Someone has to be accountable for updating inventory manually, and it is an initial problem.

The inventory is updating automatically, and numbers are coming accurately, but the supply chain manager was not receiving alerts.

Winning idea

Design a label consisting of QR codes associated with the product number.

The Google sheets and QR codes are associated; Scanning will automate the inventory update.

Custome developed functions with Google Script to trigger email alerts for low inventory. The minimum quality is customized for all the parts based on their arrival time after the order.

04

Test and Build

The first design consisted of Bar/QR code wired scanner. After testing the first version, its time consuming to work efficiently during the product assembly cycle with a wired scanner. The product building team had to take a wired scanner around the warehouse, and it was not lean practice to perform.

Alternative of wired scanner

I found a plugin by Microsoft called "Scan IT to office" that has an extension to sync with Google Sheet. It was easy for the user to use the phone for scanning and entering a quantity to update the inventory. This update in design gave users enough mobility and freedom to use their devices.

-

QR code

-

Part number

-

Part image

-

Part name

-

Product family name

Final information architecture

💡Updated Information Architecture with streamlined and automated information flow

Reflection

-

I learned how to make physical space lean and service efficient.

-

Always think about the mobility and easiness of the system so any user can understand and learn.

-

A small change in inventory can improvise finances and scheduled deliveries.